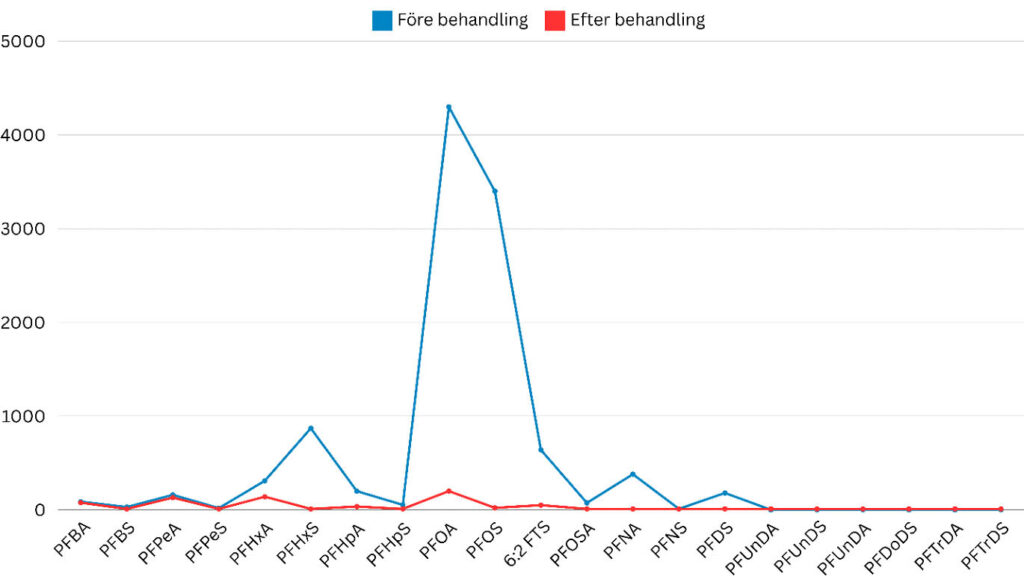

PFAS is becoming increasingly common and can be found in all types of water environments, such as groundwater, leachate, and water from other exposed areas. Meeting or even reaching the current limit values is a significant challenge. Purifying water from PFAS therefore requires advanced treatment processes. With our methods, we achieve a reduction of up to 99.5%, depending on the water’s composition and the scale of the treatment system.

Image 1 shows an illustration highlighting the high percentage of PFAS 4 and PFAS 22 removal achieved for our customers through the use of a flotation system with the addition of Fluorflok.

Figure 2 also presents analysis results and purification rates, specifically for PFAS 22.

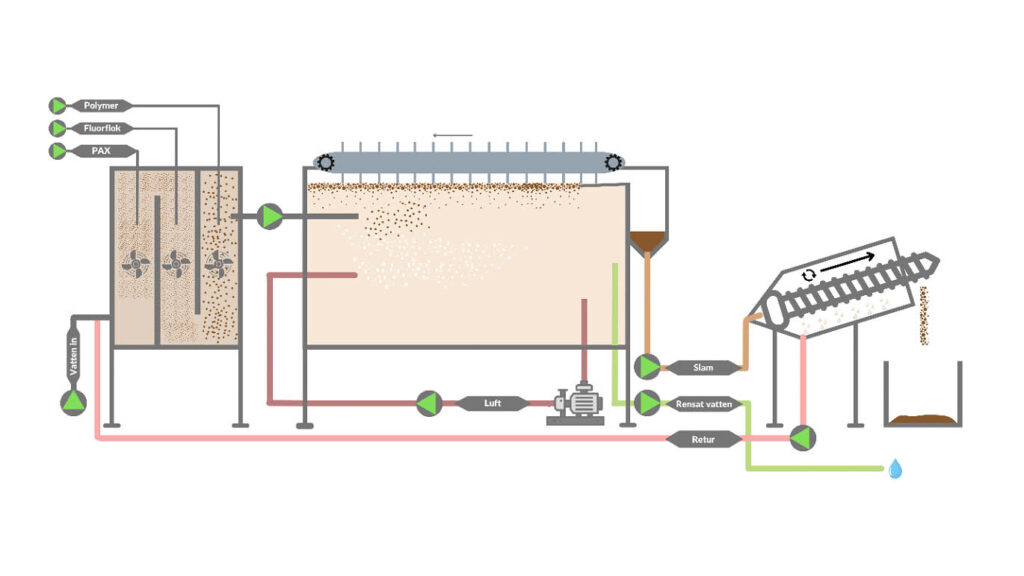

The untreated water is fed through a reactor tank with three chambers. In the first chamber, aluminum sulfate is added while stirring, forming microflocs from the suspended particles in the water. In the second chamber, Fluorflok is added, binding PFAS compounds to the microflocs. In the third chamber, a polymer is added to aggregate the microflocs into larger flocs. Through this process, the water now contains large flocs with PFAS compounds bound to them.

After flocculation, the water is directed to the flotation system, where microbubbles from a Nikuni pump lift the sludge flocs to the surface. Here, the flocs are removed with a rotating scraper, turning them into sludge. During the process, the purified water is released after the flocs have been separated.

The sludge removed during flotation is very wet, and to reduce its volume, a screw press is used. The screw press dewaters the sludge with a rotating screw, squeezing out the water, which is then redirected to the inlet. The dewatered sludge is discharged at the end of the press, significantly reducing its volume, thereby lowering operating costs and handling efforts.

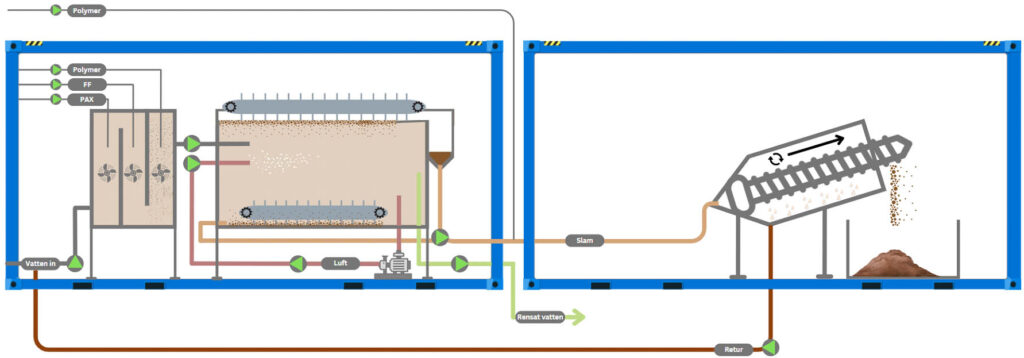

We also provide complete treatment systems as container solutions, making it easy to establish facilities in locations where constructing a permanent building or insulated shelter is not feasible.

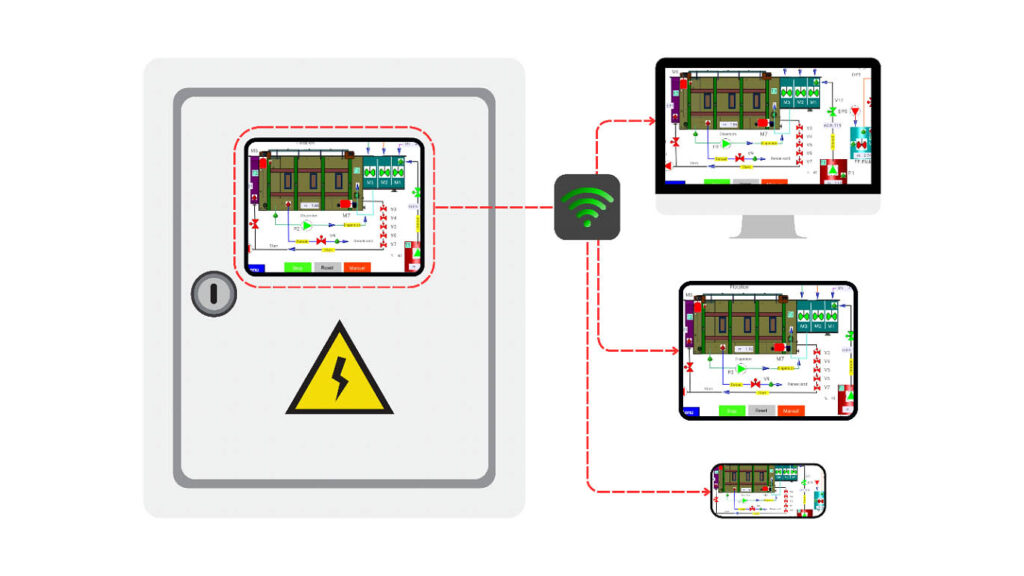

All our facilities come with network connectivity.

Installation at the customer’s premises

In-house production & workshop.

AirTURBO RV2 is an energy-efficient and compact aerator, designed to optimize oxygenation in large volumes of water

Read More

Flotation is an energy-efficient method that removes particles using microbubbles to lift contaminants to the surface.

Read More

Floating Walls control water flow and improve water quality by increasing circulation in various aquatic environments.

Read More